How fiber measurement drives green manufacturing practices in modern industry

How fiber measurement drives green manufacturing practices in modern industry

Blog Article

Recognizing the Value of Fiber Measurement in Modern Sector Applications

In today's affordable landscape, you can not overlook the relevance of fiber measurement in your operations. Recognizing the properties of fibers-- like diameter, length, and thickness-- can straight influence the high quality and performance of your products. With specific dimension methods, you're much better outfitted to decrease problems and optimize source use. However how do these techniques align with sector criteria and sustainability objectives? The answers might hold the secret to your success.

The Duty of Fiber Measurement in Product Quality Control

When you think about product high quality guarantee in markets that rely upon fiber-based materials, exact fiber dimension comes to be vital. It helps you guarantee that the fibers fulfill defined standards, inevitably influencing the final product's honesty and performance. By measuring fiber diameter, size, and density, you can identify variances that may compromise quality.Implementing specific dimension techniques allows you to keep limited control over production processes, decreasing the threat of defects. This not just improves customer complete satisfaction yet likewise decreases waste and expenses connected with rework.Using advanced measurement tools and methods, you can rapidly examine fiber properties and make educated decisions, enhancing total product efficiency. Consequently, this proactive strategy enhances your brand name's track record for dependability. Ultimately, reliable fiber dimension directly contributes to the long life and success of your items in an open market.

Effect of Fiber Quality on Efficiency and Durability

When you think about fiber buildings, strength and flexibility play a necessary duty in figuring out just how well a product performs under stress and anxiety. Additionally, moisture absorption qualities can greatly impact toughness, particularly in varying environmental conditions. Thermal resistance and stability are also essential, as they affect the long life and reliability of the fibers in useful applications.

Fiber Strength and Adaptability

Fiber strength and adaptability play a crucial duty in identifying the efficiency and longevity of numerous materials used in commercial applications. When you select fibers, you're looking for a balance in between strength and flexibility to assure your items can stand up to anxiety while keeping their form. Strong fibers stand up to breakage under tension, making them perfect for load-bearing applications. On the various other hand, flexible fibers enable movement and adaptability, which is important in textiles and compounds. If you enhance these buildings, you enhance the general capability and long life of your materials. By understanding the specific needs of your application, you can choose fibers that deliver the best mix of strength and versatility, inevitably boosting item performance and dependability sought after settings.

Wetness Absorption Characteristics

Wetness absorption attributes substantially affect the efficiency and longevity of fibers in numerous industrial applications. When you consider fibers, their capability to absorb wetness can establish how well they'll carry out under various problems. High wetness absorption may bring about swelling, which can impact the fiber's stamina and adaptability. It can also advertise mold and mildew or mildew development, endangering the product's stability. On the other hand, reduced wetness absorption can boost toughness, making the fibers much more resistant to ecological factors. You'll wish to choose fibers based on their dampness absorption residential properties to guarantee peak efficiency in your specific application. By doing so, you can significantly improve the longevity and dependability of the end product, inevitably improving its worth in the marketplace.

Thermal Resistance and Stability

While thinking about the performance and toughness of products, thermal resistance and stability play considerable functions in fiber applications. You require to assess exactly how fibers respond under differing temperature levels, as this can directly influence their durability and performance. High thermal resistance means that fibers can hold up against severe heat without degrading, making them appropriate for applications like insulation and vehicle parts. Furthermore, security warranties that fibers keep their buildings in time, even when subjected to changing thermal problems. By determining these features, you can pick the appropriate products for your specific requirements, assuring peak efficiency. Bear in mind, the appropriate fiber residential or commercial properties can boost durability and reduce maintenance expenses, eventually causing much better general product efficiency.

Methods and Technologies for Accurate Fiber Measurement

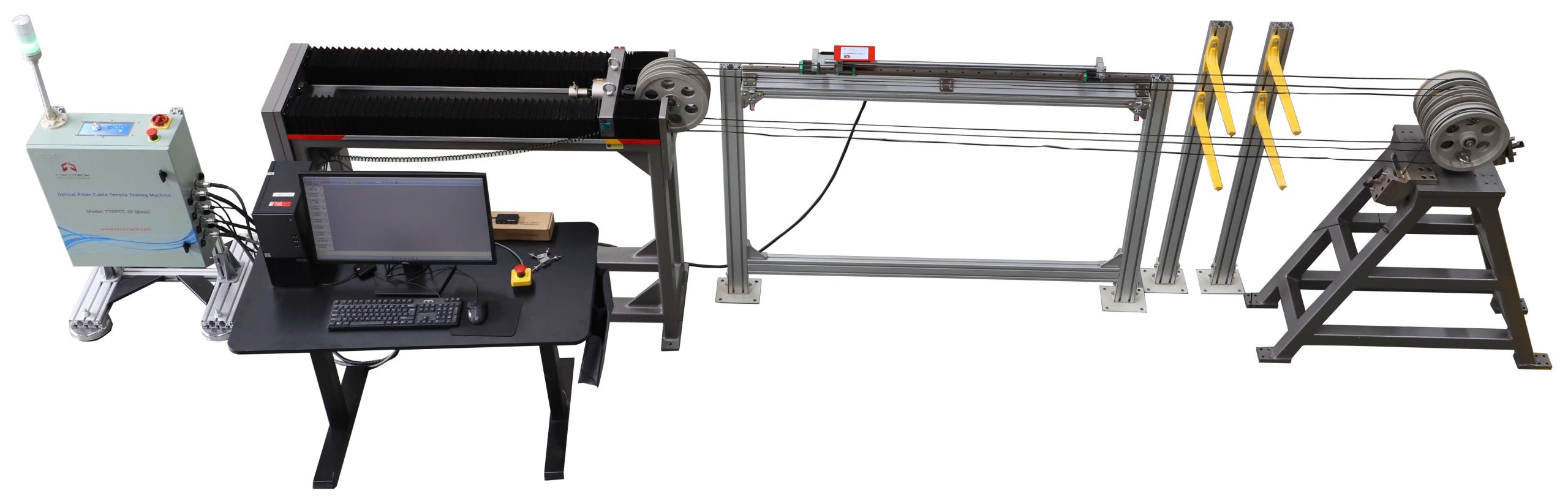

When determining fiber accurately, using the right strategies and modern technologies is essential for attaining reliable outcomes. You can begin by making use of optical microscopy, which permits you to observe fiber framework and morphology with precision. Next, think about utilizing laser diffraction methods for determining fiber size, as they offer rapid and non-destructive measurement.Another reliable strategy is making use of image evaluation software application, which automates the processing of fiber images, enhancing accuracy and effectiveness. You should additionally check out sophisticated approaches like vibrant mechanical analysis (DMA) to assess mechanical residential or commercial properties and efficiency under various conditions.For real-time monitoring, incorporating sensors with digital data acquisition systems can provide continual fiber measurements, assuring regular top quality control. Constantly preserve calibration and validation methods for your measurement devices to confirm precision. By incorporating these methods and modern technologies, you'll accomplish reliable fiber dimensions crucial for your industry applications.

Industry Requirements and Compliance in Fiber Measurement

When it comes to fiber measurement, recognizing industry standards and compliance is crucial for your procedures. You'll need to remain informed about regulative needs that influence your processes and warranty that your measurement strategies align with well-known standards. This not only aids keep top quality however additionally enhances your trustworthiness in the market.

Regulatory Compliance Requirements

As sectors progressively rely upon fiber dimensions, understanding regulatory compliance needs becomes vital for ensuring product top quality and security. You require to stay educated concerning particular regulations that control fiber screening and measurement in your field. Compliance with these guidelines helps avoid pricey penalties and guarantees that your items meet safety and security requirements. Key guidelines might include those established by companies like ASTM, ISO, and ANSI, which detail approaches for exact fiber dimension. By adhering to these standards, you not just enhance product stability yet also foster depend on with clients and stakeholders. It is essential to execute strenuous screening protocols and preserve ideal documents to show compliance, ensuring you fulfill both legal and market needs properly.

Standardization of Measurement Techniques

Standardization of dimension strategies is crucial for achieving regular and trustworthy fiber evaluations across different industries. When you take on standardized techniques, you ensure that your dimensions straighten with industry standards, making your outcomes similar and credible. This consistency assists in quality control, enabling you to identify discrepancies promptly and take rehabilitative activities. It likewise simplifies compliance with governing demands, as standard strategies typically meet or surpass industry standards. By carrying out these methods, you improve your reliability with stakeholders and customers, fostering rely on your products. Furthermore, standardized methods can enhance training processes for your team, permitting them to become more proficient in fiber dimension. Inevitably, embracing standardization can result in boosted operational efficiency and far better overall results.

Enhancing Manufacturing Effectiveness With Fiber Measurement

To boost production efficiency, integrating fiber dimension into commercial processes can make a substantial difference. By accurately determining fiber homes, you can maximize basic material usage and lower waste, straight impacting your bottom line. You'll discover that exact fiber dimensions aid streamline production by making sure uniformity in item quality, which reduces downtime and rework.When you execute real-time fiber measurement modern technologies, you obtain prompt understandings right into your processes. This permits you to make fast changes, boosting throughput and boosting general performance. In addition, recognizing fiber features can bring about much better maker setups, minimizing power usage and enhancing equipment lifespan.Ultimately, effective fiber measurement encourages you to make data-driven choices, bring about smoother operations and higher productivity. By focusing on fiber dimension, you're not just boosting performance; you're setting the structure for long-lasting success in Full Article your industry.

The Link Between Fiber Measurement and Sustainability

Incorporating fiber dimension not only boosts manufacturing performance yet also plays an essential role in advertising sustainability within industrial processes. By precisely determining fiber content, you can reduce waste and maximize resource use. This indicates you're not just conserving products but likewise minimizing energy intake and greenhouse gas discharges connected with production.When you comprehend the fiber attributes in your navigate here materials, you can make educated decisions that bring about even more lasting techniques. Utilizing the appropriate fiber blends can improve product durability, which in turn lowers the frequency of substitutes and lowers total environmental impact.Moreover, exact fiber dimension helps in conformity with sustainability regulations, making certain that your operations line up with green standards. As consumers progressively prioritize sustainable items, your commitment to responsible fiber dimension can boost your brand track record and meet market demands. Highlighting sustainability via fiber dimension can bring about a much more effective, liable, and profitable operation.

Future Fads in Fiber Measurement and Industry Advancement

As sectors advance, staying ahead in fiber dimension modern technology becomes necessary for technology and competitiveness. You'll observe that innovations in automation and artificial intelligence are driving more exact and efficient measurement processes. Embracing these technologies enables you to lower mistakes and improve efficiency, providing you an edge over competitors.Moreover, the integration of real-time data analytics is changing just how you check fiber top quality and efficiency. With instant understandings, you can make educated decisions that lead to boosted item results. Sustainability patterns are likely to press technologies in environmentally friendly fiber materials, requiring exact dimension strategies to ensure compliance and quality.In addition, anticipate to see boosted use of wise sensors that give continual tracking, permitting positive adjustments in manufacturing. By embracing these future trends, you'll place your business to grow in an ever-evolving landscape, ensuring you meet both market needs and sustainability goals.

Regularly Asked Questions

Just How Does Fiber Measurement Effect Customer Safety Regulations?

Fiber dimension directly impacts customer safety and security policies by ensuring items meet top quality requirements. It aids recognize harmful impurities, guiding producers to provide much safer items. You gain from these policies with enhanced product security and openness.

What Industries Prioritize Fiber Dimension the A Lot Of?

Exist Any Type Of Health Threats Connected With Unreliable Fiber Measurements?

Yes, imprecise fiber measurements can lead to wellness dangers like digestive concerns and nutrient deficiencies. fibre testing equipment. It's important you assure precision in fiber content, as inappropriate levels can influence your overall wellness and wellness

Just How Can Small Companies Carry Out Fiber Dimension Practices?

You can start by investing in trusted fiber measurement devices, look at this now training your personnel on finest methods, and on a regular basis examining your products. Working together with specialists can also aid guarantee accuracy and enhance your overall quality assurance procedures.

What Are the Expenses Linked With Fiber Measurement Technologies?

The prices connected with fiber dimension technologies vary commonly. You'll require to examine tools, maintenance, training, and potential software application (optical measurement system). Spending carefully can improve item top quality, but make sure you budget plan accordingly for long-term benefits

Report this page